Why Rare Earths Matter More Than Ever

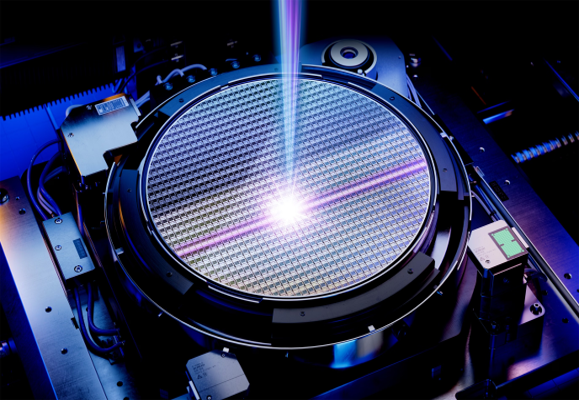

Strategic Materials in Semiconductor Manufacturing

As the semiconductor industry pushes toward more advanced, efficient, and compact devices, the conversation around strategic materials, especially rare earth materials is growing louder. These materials are no longer a footnote in the supply chain, they’re now central to innovation, security, and competitiveness.

Permag™, comprised of Dexter Magnetic Technologies, Electron Energy Corporation (EEC), and Magnetic Component Engineering (MCE), is at the forefront of supporting semiconductor innovation with decades of magnetic materials expertise and a secure, global supply chain.

What Are Strategic Materials—and Why Do They Matter?

Strategic materials are critical to national security, industrial capability, and technological leadership. In the semiconductor sector, this includes specialty gases, ultra-pure silicon, and—most notably—rare earth elements used in high-performance magnets.

Magnets made from rare earth materials are used in nearly every semiconductor process step—from wafer handling and stepper stages to vacuum chambers and ion implantation systems. They drive motors, stabilize positioning systems, and enable the precision modern chipmaking requires.

When the next generation of chips rolls out, the industry must be ready. The opportunity comes in cycles. If companies aren’t positioned with the right materials at the right time, someone else will be—and they’ll miss the peak.

Why “Rare” Earths Aren’t Actually Rare

The name “rare earth” is a bit misleading. Rare earth elements, including neodymium, samarium, dysprosium, and terbium, are relatively abundant in the Earth’s crust. But they’re rarely found in high concentrations, making extraction and purification complex and expensive.

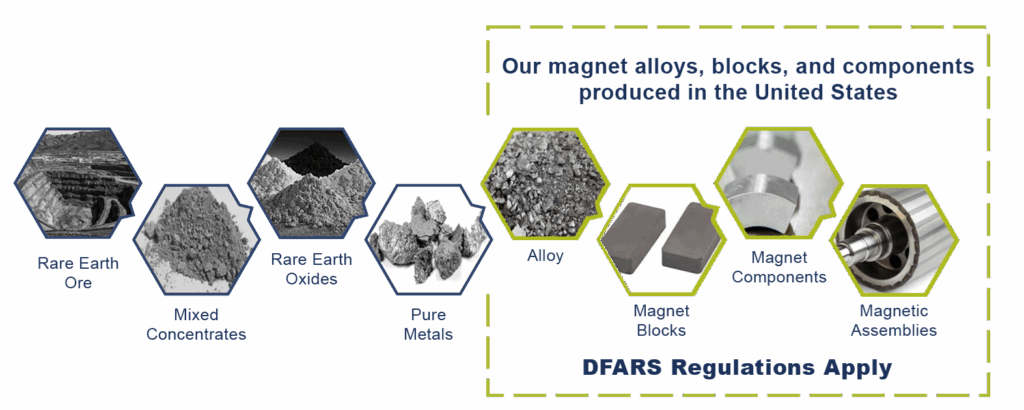

Refining these materials into usable forms involves multiple steps:

- Ore crushing and milling

- Chemical separation of rare earth oxides

- Solvent extraction and purification

- Reduction and alloying into magnetic metals

- Precision magnet manufacturing

Through Electron Energy Corporation (EEC), Permag™ is home to the only U.S. manufacturer of samarium cobalt magnets—a critical advantage for semiconductor applications that require high performance in extreme environments. EEC’s capabilities ensure domestic, DFARS-compliant sourcing for this vital rare earth magnet alloy.

What is DFARS?

DFARS stands for the Defense Federal Acquisition Regulation Supplement—a set of requirements that ensure materials used in U.S. defense and aerospace applications are sourced from approved, secure, and often domestic suppliers. DFARS compliance is essential for companies working on defense-related or government-funded projects.

Shifting Geopolitics: A Wake-Up Call for Supply Chains

For years, rare earth materials were inexpensive and readily available. But recent geopolitical tensions—particularly between the U.S. and China—have turned what was once a stable supply into a strategic vulnerability.

Recognizing the risk, the U.S. and allied governments are actively reshoring rare earth production, investing in domestic mining and processing, and encouraging supplier diversification.

Permag™ has long been ahead of this curve. With over 170 years of combined experience in magnetic materials and manufacturing, we’ve built a stable, diversified global supply chain—ensuring our customers have access to critical materials when and where they need them.

Prepare Now for the Next Cycle

The semiconductor industry never stops evolving—and the next leap in chip performance is always around the corner. When that moment comes, you’ll need to move fast. Delays in securing strategic materials could mean lost contracts, delayed launches, and missed revenue peaks.

Permag™ ensures you won’t miss the opportunity. With unmatched technical expertise, domestic manufacturing, and global supply chain resilience, Permag™ has the materials—when you need them.