The Guide to Magnetics in Surgical Robotics

Selection, Design, and Customization

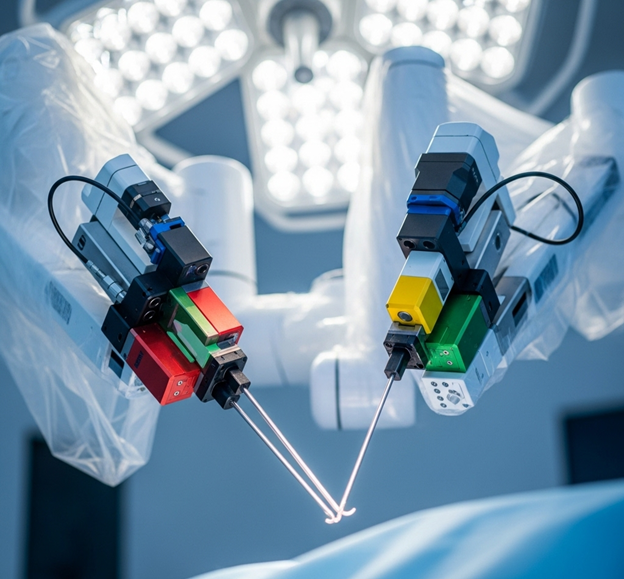

What makes a surgical robot as precise as the surgeon guiding it? Motors, sensors, and software matter, but the answer starts deeper: in the magnetic components at its core.

Whether enabling ultra-compact actuation, delivering haptic feedback, or holding tools with surgical-grade accuracy, magnets are often the silent enablers of performance in robotic systems. But they’re also misunderstood, and under-optimized. This guide breaks down how smart magnetic design powers innovation in surgical robotics, and how Permag helps engineering teams get it right the first time.

Why Magnets Matter in Surgical Robotics

Magnets are foundational to surgical robotic platforms. Here’s how they show up in the operating room:

- Actuation: Rare-earth magnets in miniature motors provide torque in tight spaces, powering robotic joints and wristed instruments.

- Feedback & Sensing: Magnetic encoders and Hall-effect sensors enable precise positional control, essential for force feedback and closed-loop control.

- Magnetic Coupling: Contactless transmission of force via magnetic couplings ensures sterile, sealed environments.

- Tool Retention: Custom magnet arrays allow for rapid tool exchanges and safe magnetic holding during surgery.

Selecting the Right Magnet: What Design Engineers Should Consider

Designing for surgical robotics means solving a multidimensional puzzle. Here are the key magnetic factors to consider:

- NdFeB (Neodymium-Iron-Boron): Ideal for high-strength, small-form-factor needs. However, it’s prone to corrosion and often requires coating.

- SmCo (Samarium Cobalt): Excellent thermal stability and corrosion resistance. Preferred for extreme environments and higher biocompatibility.

2. Geometry & Tolerances

- Miniature actuators require magnets with sub-millimeter precision.

- Tight tolerances reduce wobble, improve efficiency, and enhance sensor feedback.

- Parylene C, gold, and titanium coatings protect against corrosion and support ISO 10993 biocompatibility testing.

- BarrierMax™ coatings are custom-designed for harsh sterilization cycles.

Custom Magnetic Assemblies: The New Standard in Surgical Robotics

OEMs require more than off-the-shelf solutions. They need integrated assemblies engineered for:

- Sterilization: Autoclave, gamma, and EtO compatibility

- Miniaturization: Micro-rotors, insert-molded arrays, and non-magnetic housing

- Cleanroom Assembly: ISO 7 environments for contamination control

- Integrated Validation: Lifecycle testing, helium leak tests, and magnetic field mapping

Why Partner with Permag?

You bring the robotic innovation. We bring the magnetic foundation. Permag offers:

- ISO 13485 certified cleanroom manufacturing

- In-house engineering support and FEA magnetic modeling

- Decades of experience across implantables, surgical robotics, and active devices

Ready to Start Your Magnetic Design Journey?

If you’re designing the next-generation robotic system and need custom magnetics built for safety, scale, and performance, our team is ready to help.