Why it matters:

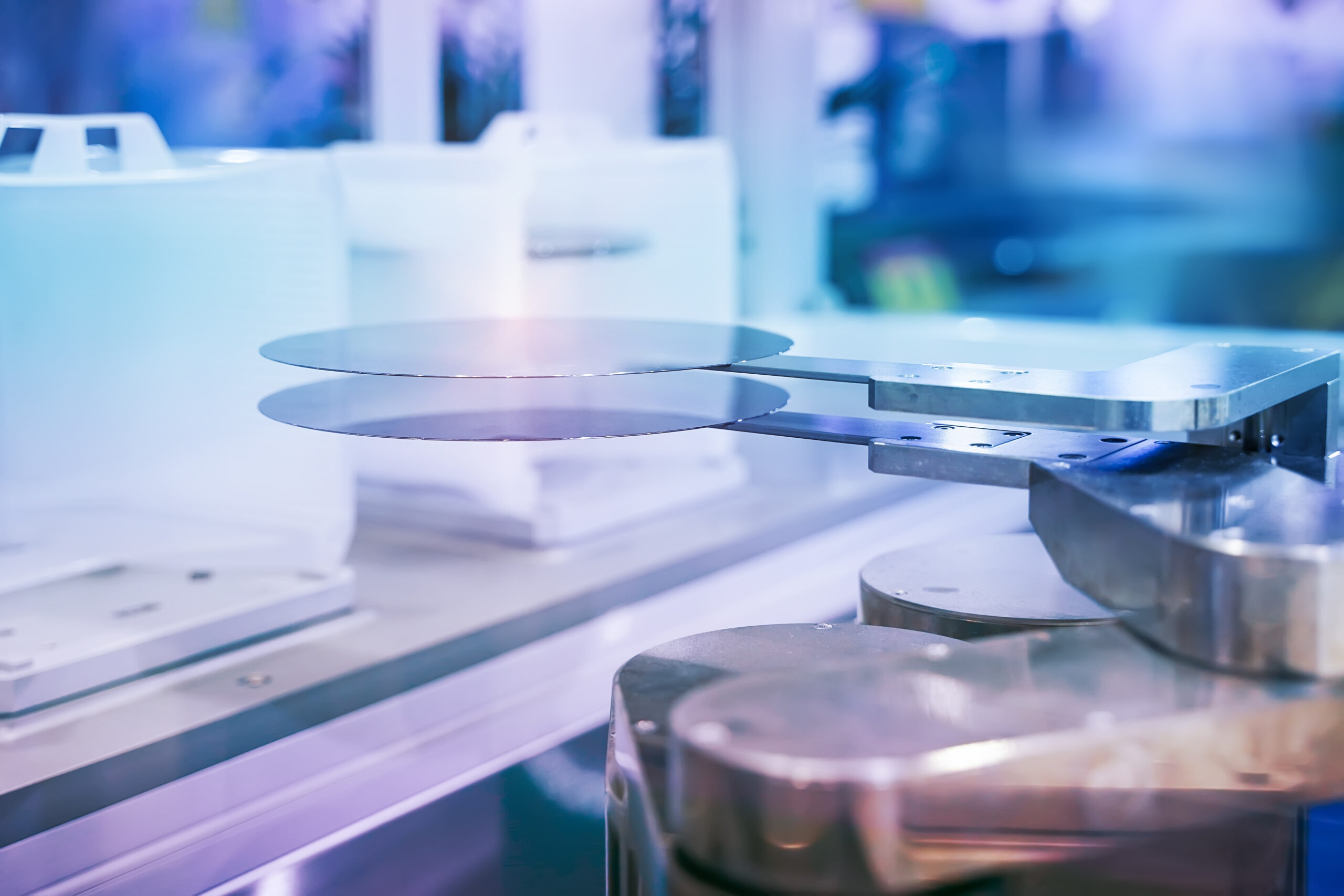

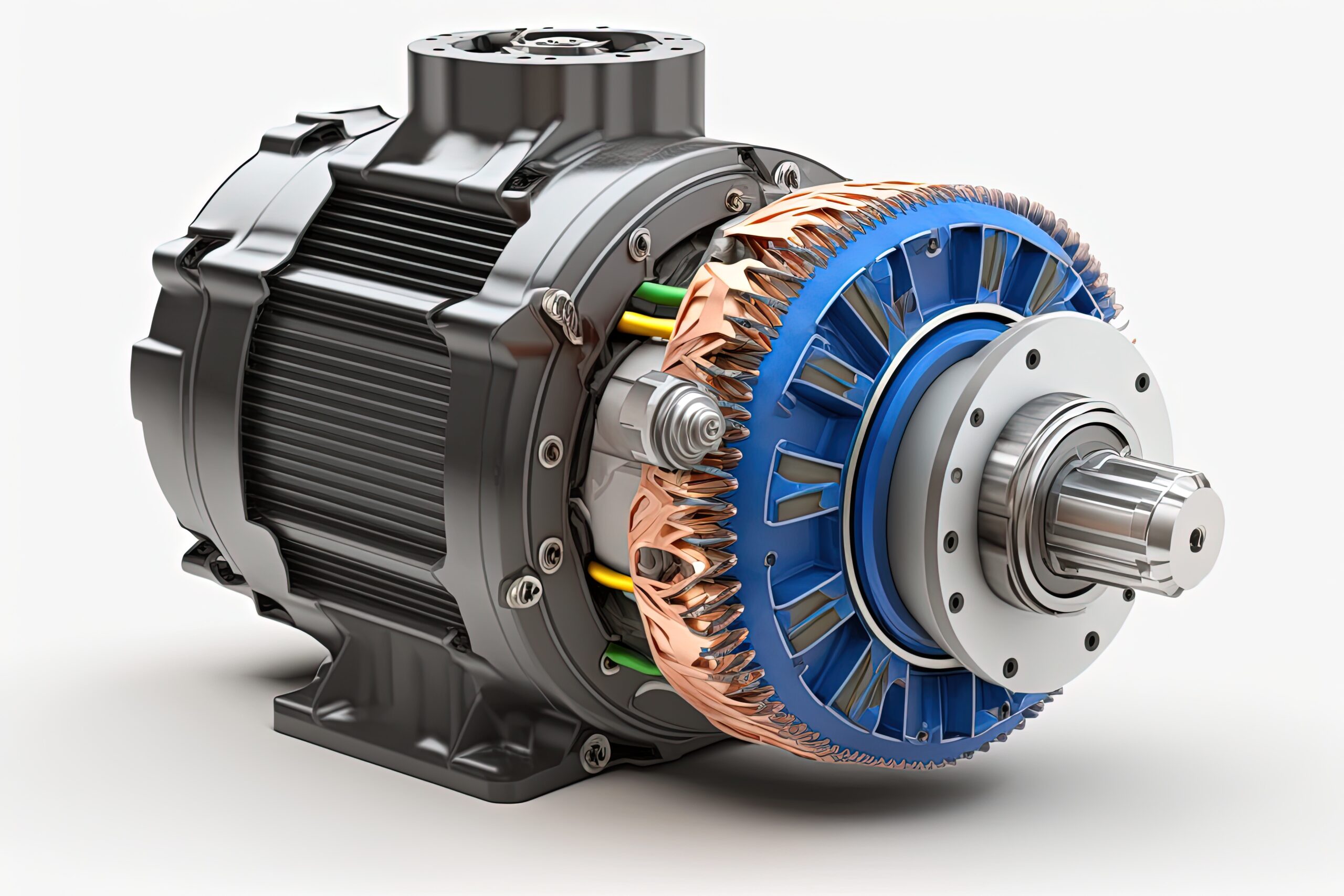

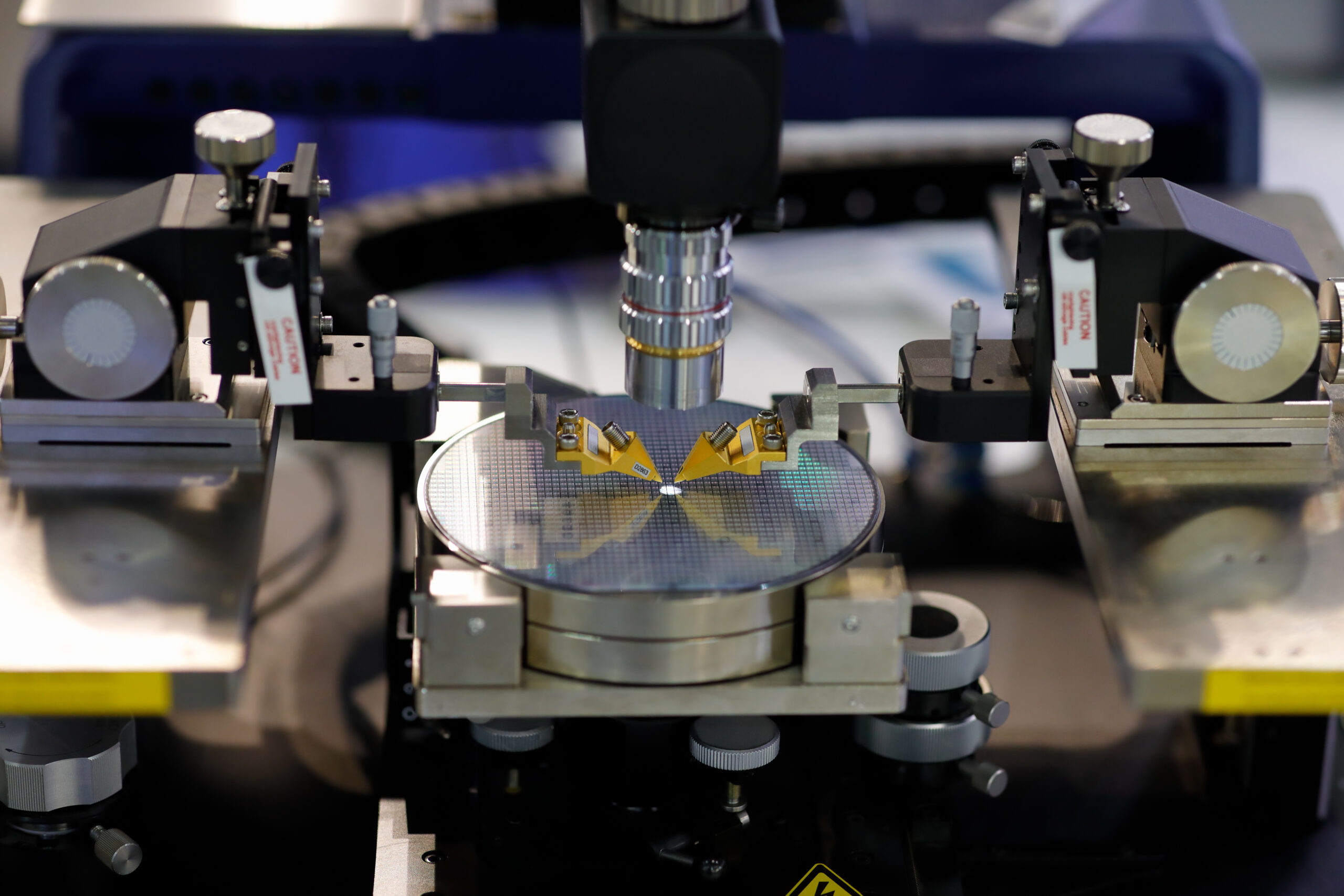

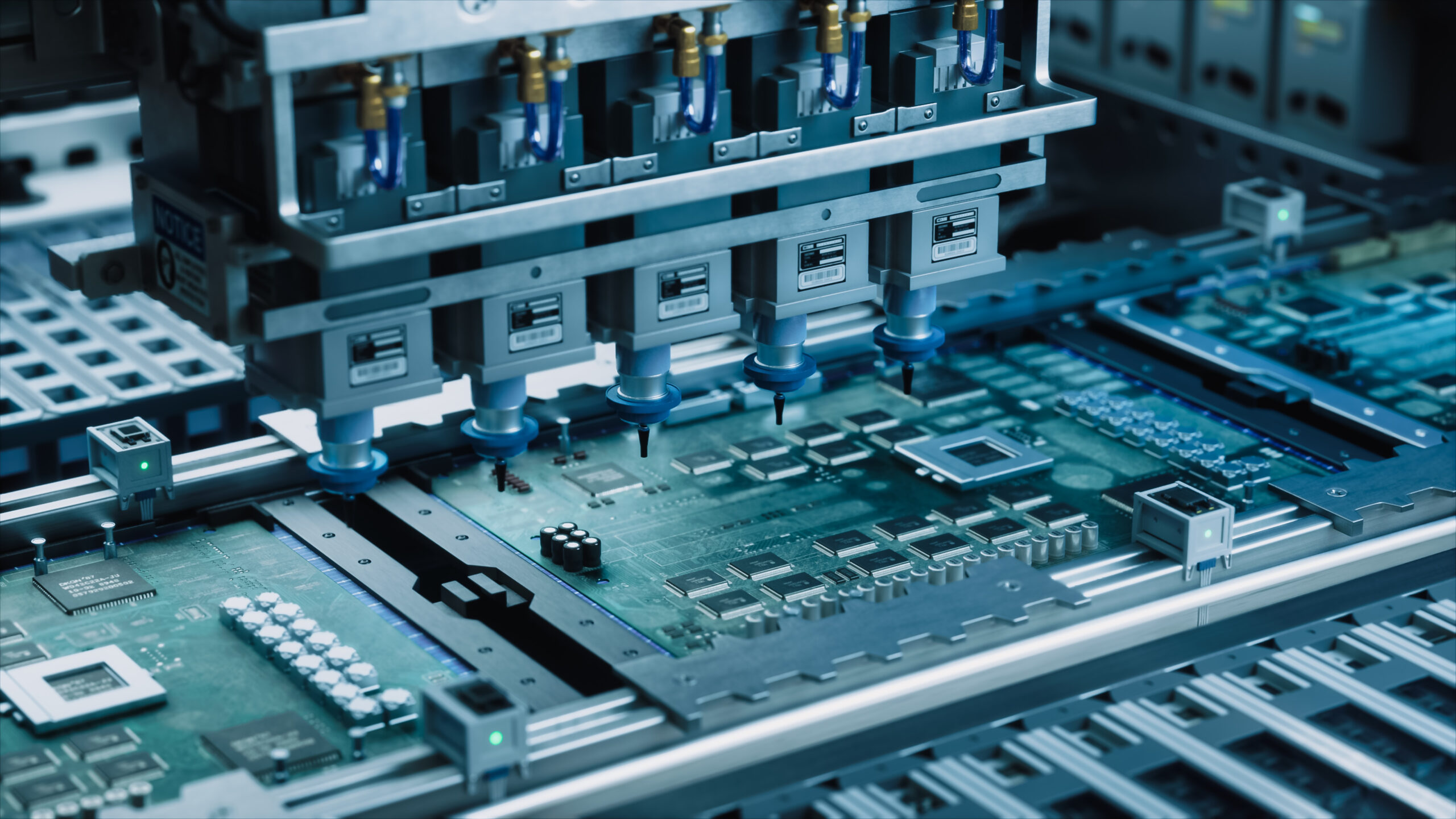

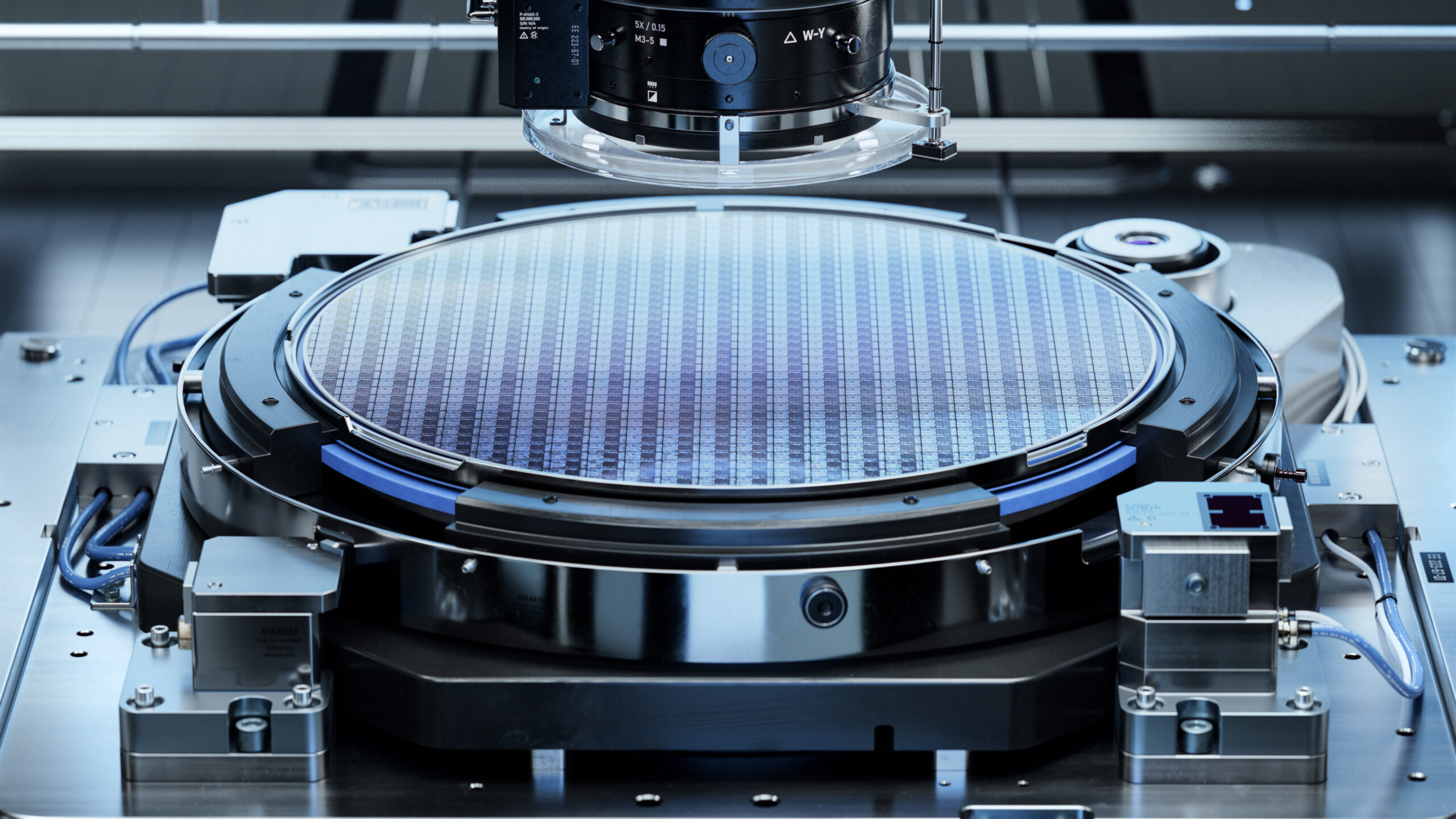

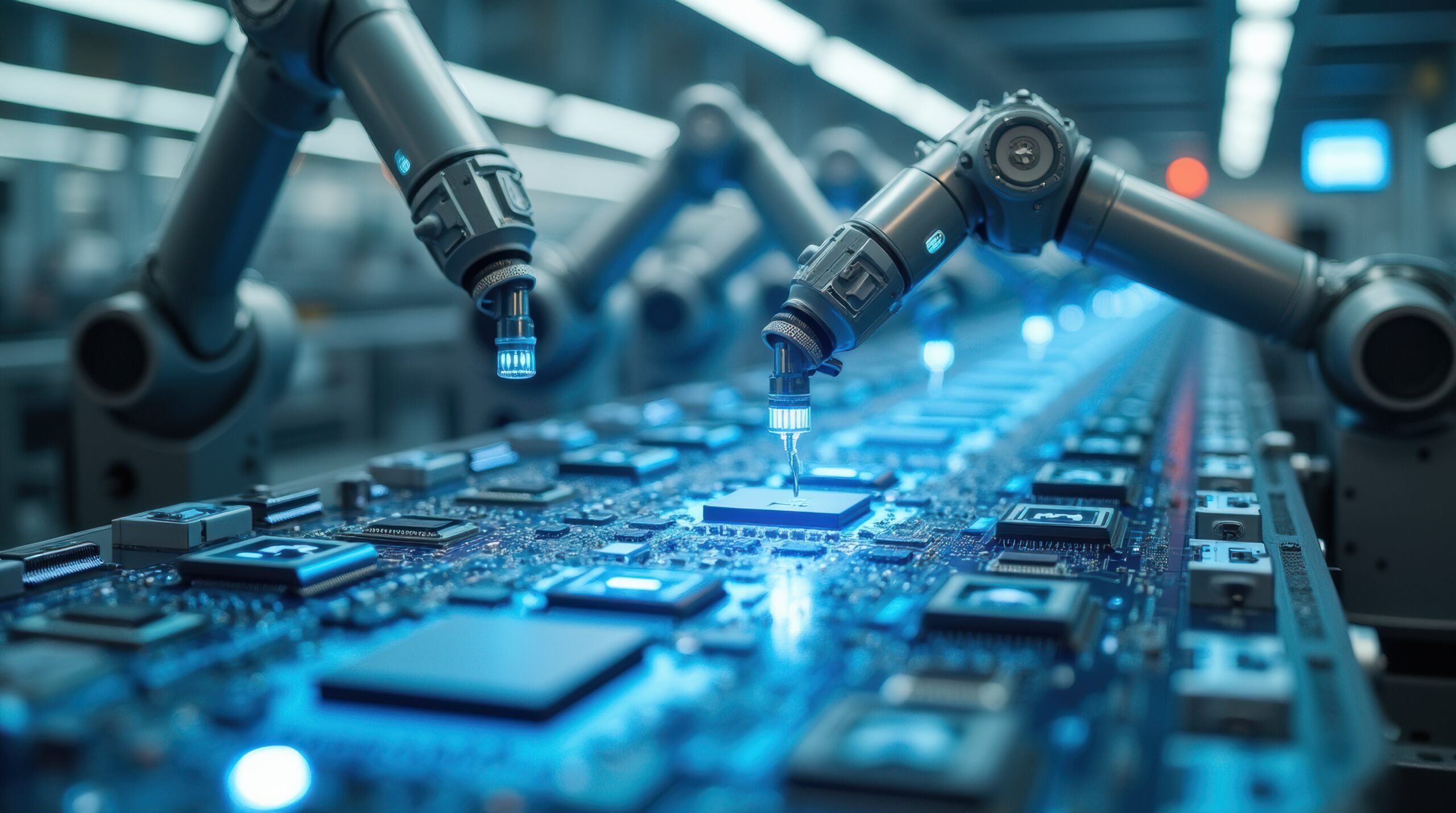

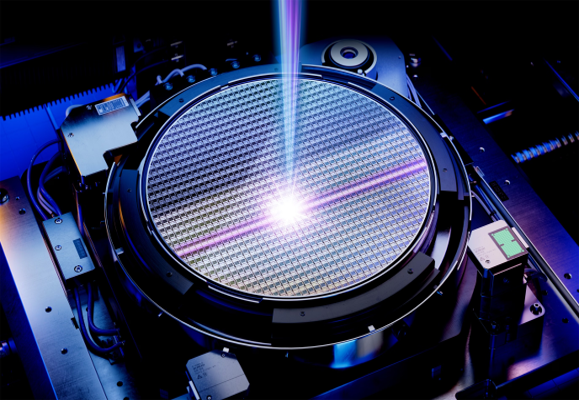

- Process variation or magnetic inconsistency can affect tool performance, wafer handling, and system reliability

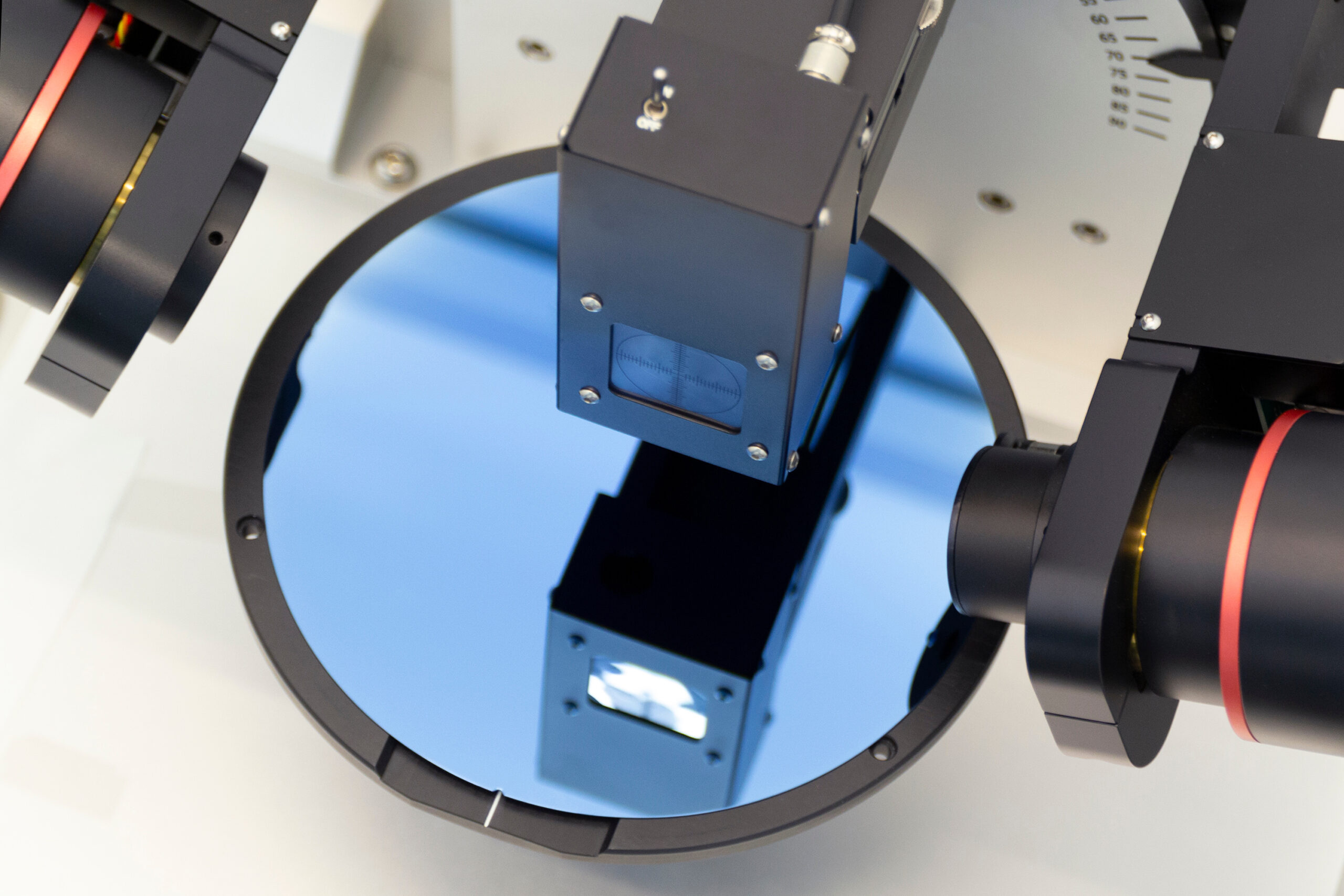

- Tight tolerances and repeatability are critical to maintaining yield and minimizing downtime

- Documentation, traceability, and process control are essential for qualification and long-term support

What Permag Does:

- Implements rigorous quality management systems to ensure consistent magnetic performance lot-to-lot

- Maintains tight process controls, inspection protocols, and full material traceability

- Partners closely with customers to support qualification, validation, and long-term production requirements