How Magnets Make Space Thrusters Possible

When most people think about aerospace propulsion, they picture engines, propellants, and advanced spacecraft design. What often goes unnoticed is the critical role rare earth magnets play in making modern thrusters reliable, efficient, and capable of meeting the demands of space. From commercial satellites to deep-space missions, magnets are the unseen force shaping the future of propulsion.

Thrusters

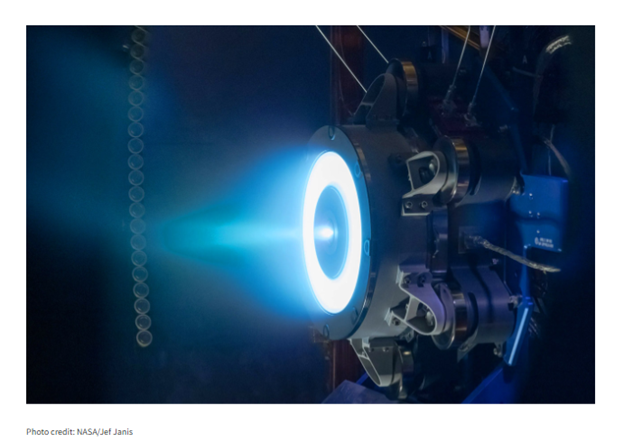

Thrusters are the backbone of orbital maneuvering and long-duration missions. Unlike traditional chemical propulsion, which provides powerful but short-lived thrust, advanced thrusters—such as Hall-effect and ion thrusters—deliver continuous, efficient performance. They are widely used for satellite station-keeping, orbital transfers, and deep-space exploration.

At the heart of these systems are magnetic fields that accelerate and guide ionized particles. Without strong, stable, and precisely engineered magnets, these propulsion technologies simply wouldn’t work.

Why Rare Earth Magnets Matter

Rare earth magnets like Samarium Cobalt (SmCo) and Neodymium Iron Boron (NdFeB) are essential to thruster performance.

- Samarium Cobalt (SmCo): Offers exceptional high-temperature stability and resistance to radiation, making it ideal for the harsh environments of space. SmCo maintains magnetic strength where other materials would degrade, ensuring long-term reliability.

- Neodymium Iron Boron (NdFeB): Known for its unmatched magnetic strength, NdFeB allows for more compact thruster designs with high field intensity. While it is less thermally stable than SmCo, it is often used where size and weight reduction are critical.

Together, these materials provide the foundation for propulsion systems that balance strength, efficiency, and resilience.

Built for Harsh Aerospace Environments

Operating in space exposes thrusters to some of the most extreme conditions imaginable. Temperatures swing hundreds of degrees, radiation is constant, and systems must function flawlessly for years without maintenance. In these environments, material choice is more than a design decision—it’s mission critical.

Rare earth magnets outperform alternatives like ferrites or Alnico by resisting demagnetization, maintaining stability under thermal stress, and delivering the performance needed for long-duration aerospace applications. This reliability directly translates to mission success, reducing risk and cost while extending spacecraft lifespans.

The Reliability Link

The success of any propulsion system is directly tied to the reliability of its materials. Thrusters equipped with high-performance rare earth magnets benefit from:

- Precision: Stable fields that enable accurate maneuvering and payload control.

- Longevity: Resistance to degradation that extends operational lifetimes.

- Efficiency: High energy conversion that reduces fuel requirements and overall system weight.

These advantages are especially critical in commercial aerospace, where satellite constellations, CubeSats, and exploratory missions demand both affordability and dependability.

Supply Chain and Sustainability

The increasing demand for thrusters in both defense and commercial aerospace has put rare earth materials in the spotlight. Global supply chain concerns—particularly around sourcing outside of China—make security, compliance, and diversification vital.

Permag™ is committed to ensuring a stable, DFARS-compliant supply of rare earth magnets, with decades of expertise in Samarium Cobalt production in the United States and strategic sourcing across North America and Europe. This secure supply chain allows aerospace companies to move forward with confidence, knowing their missions are backed by materials they can rely on.

Looking Ahead

As the commercial aerospace industry grows—driven by satellite networks, advanced air mobility, and exploration beyond Earth’s orbit—the need for reliable thruster technology will only intensify. Rare earth magnets will remain the hidden force enabling these propulsion systems to meet ambitious mission profiles.

At Permag, we combine a secure rare earth supply chain with advanced engineering and manufacturing expertise to deliver magnetics that perform in the most critical aerospace environments. Our solutions help ensure thrusters aren’t just powerful, but dependable—paving the way for the next generation of aerospace innovation.